Wiedza i doświadczenie producenta wyposażenia fabrycznego w zakresie części zamiennych

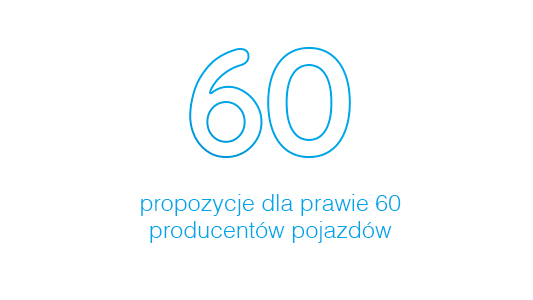

Nasza pozycja jako producenta cześci OEM zapewnia nam zaufanie największych producentów samochodów. Pełna oferta dotycząca pasków rozrządu i akcesoriów pomocniczych, obejmuje prawie 94% zapotrzebowania europejskiego parku samochodowego.

Gwarantujemy:

- jakość części zamiennych, zgodną ze specyfikacją producenta

- niezawodność

- wydajność

- innowacyjność potwierdzoną testami w celu dostarczania na rynek "produktów przyszłości"

- wsparcie i komunikację techniczną

Rozrząd SNR: pełna gama od dostawcy oem

Nasza oferta, dzięki podwójnej: europejsko-japońskiej tożsamości firmy, pokrywa ogromną część zapotrzebowania europejskich i azjatyckich marek pojazdów.

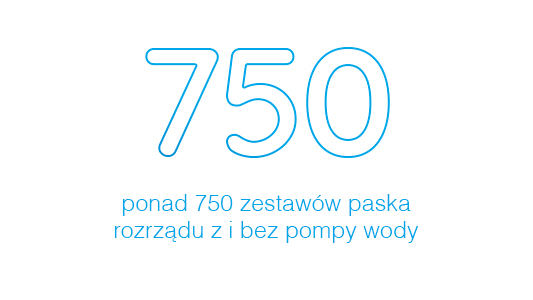

Zestawy paska rozrządu z oraz bez pompy wody

Podobnie jak sam pasek rozrządu, rolki i pompa wody również się zużywają, dlatego też należy je wymieniać podczas serwisowania układu rozrządu. Zużycie któregokolwiek z powyższych elementów może skutkować awarią silnika.

NTN oferuje kompletne zestawy, zapewniające najwyższą jakość wszystkich zawartych w nich elementów. Dzięki temu wszystkie potrzebne do naprawy części będziesz miał pod ręką, eliminując jednocześnie ryzyko błędu w doborze elementów.

Zestawy paska rozrządu SNR z oraz bez pompy wody zawierają wszystkie części potrzebne do prawidołowej wymiany:

- Rolki: Statyczne rolki napinające, montowane na wsporniku lub mimośrodowo, automatyczne dynamiczne rolki napinające, napinacze hydrauliczne i rolki zwrotne (zębate, kołnierzowe lub standardowe).

- Paski: w celu zwiększenia wytrzymałości na stale rosnące obciążenia i wydłużenia żywotność części, stosuje się paski wzmocnione oraz paski typu HT wykonane z teflonu lub kevlaru. NTN oferuje precyzyjne rozwiązania techniczne wybrane przez producenta pojazdu.

- Pompa wody: NTN posiada ogromne doświadczenie w produkcji oryginalnego wyposażenia. Nasze fabryki produkują ponad milion łożysk do pomp wodnych rocznie.

- Osprzęt: Śruby, nakrętki, uszczelki itp.

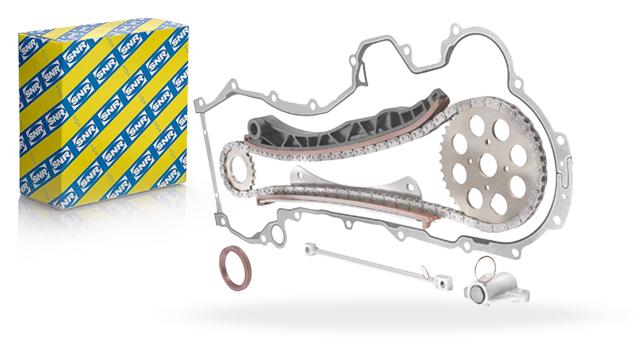

Zestawy łańcuchów rozrządu

Coraz więcej pojazdów zjeżdża z linii montażowych producentów z układami rozrządu napędzanymi łańcuchem. Pomimo swoich zalet (żywotność, bardziej kompaktowy rozmiar silnika), silnik z łańcuchem rozrządu podlega takim samym obciążeniom jak silnik z paskiem rozrządu.

Dlatego też zestaw łańcucha musi być sprawdzany w regularnych odstępach czasu, łańcuch rozrządu może wymagać wymiany, aby przywrócić silnikowi pierwotny poziom wydajności.

NTN oferuje gamę 100 zestawów łańcuchów, które z powodzeniem zaspokajają potrzeby rynku.

Każdy zestaw zawiera:

- Łańcuch: umieszczony w bloku silnika. Jego zadaniem jest synchronizacja wałka rozrządu, pompy wtryskowej i wału korbowego.

- Napinacze hydrauliczne: składające się z kilku elementów (sprężyn, cylindrów, tłoczyska i uszczelek). Montowane są one w naszych fabrykach NTN, zaś ich praca regulowana jest poprzez ciśnienie w układzie smarowania silnika.

- Ślizgi: przeznaczone do prowadzenia i/lub napinania łańcucha.

- Koła łańcuchowe i VVT: kluczowe elementy, po których porusza się łańcuch rozrządu. Są to koła zębate, których konstrukcja i orientacja zębów mają kluczowe znaczenie dla idealnej synchronizacji z łańcuchem. Koła zębate zmiennych faz rozrządu (VVT) umożliwiają optymalizację wlotu i wylotu powietrza w silniku.

Główne i pomocnicze elektryczne pompy wodne

Mając na uwadze nowe wymagania rynku, NTN oferuje gamę elektrycznych pomp wody, w tym 7 numerów referencyjnych do zastosowań w pompach głównych i ponad 40 do pomocniczych elektrycznych pomp wody.

Główne elektryczne pompy wodne

Pompy te zostały zaprojektowane w celu zapewnienia chłodzenia i utrzymania stałej temperatury w silnikach spalinowych.

Pojazdy elektryczne również posiadają wydajne systemy chłodzenia: są one wykorzystywane do optymalizacji żywotności akumulatora i zagwarantowania optymalnej wydajności, zwłaszcza podczas procesu szybkiego ładowania.

Takie pojazdy wymagają wielu obwodów chłodzenia. Istnieją dwa rodzaje systemów chłodzenia dla pojazdów elektrycznych: chłodzenie cieczą i chłodzenie powietrzem.

Pomocnicze elektryczne pompy wodne

Służą one do chłodzenia turbosprężarki i oleju skrzyni biegów lub do gromadzenia ciepła i dostarczania gorącego powietrza do przedziału pasażerskiego, gdy włączone jest ogrzewanie. Niektóre pojazdy z silnikami spalinowymi, hybrydowymi i elektrycznymi mają nawet cztery elektryczne pompy wody.

Gama akcesoriów SNR: wszystkie części zamienne do całego systemu pomocniczego

Nasza oferta komponentów pomocniczych jest jedną z najbardziej kompletnych na rynku i obejmuje paski pomocnicze, napinacze, zestawy pomocnicze, koła pasowe tłumika drgań, zestawy kół pasowych tłumika drgań, koła pasowe alternatora, łożyska klimatyzacji...

Zestawy pomocnicze z i bez pompy wodnej

To kompletne rozwiązanie naprawcze obejmujące pasek pomocniczy, napinacze, koło zębate i wszelkie inne niezbędne elementy. Zestawy pomocnicze z pompami wody zawierają również napinacz paska pomocniczego i koło zębate.

Zaleta zestawu?

- Wszystkie niezbędne komponenty w jednym pudełku

- Brak problemów z identyfikacją

- Jeden numer referencyjny dla całego zestawu

- Gwarantowana jakość części OE

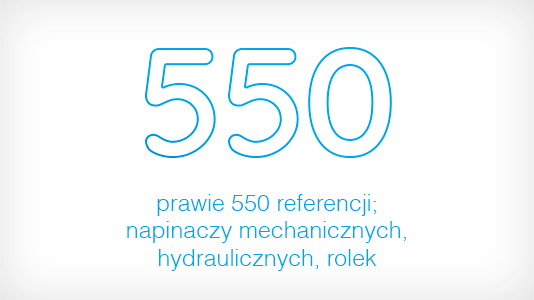

Rolki paska osprzętu

Rolki prowadzące i napinające zapewniają prawidłowe napięcie paska pomocniczego. Umożliwiają one kompensację drgań skrętnych elementów napędzanych, a także kompensują proces rozciągania paska spowodowany zużyciem. Wybór dobrej jakości napinaczy jest kluczowy dla silnika.

Technologia NTN:

- napinacze automatyczne: absorbują przejściowe duże obciążenia, zapobiegają ślizganiu się paska i redukują hałas.

- napinacze mechaniczne: absorbują ruch za pomocą sprężyny napinającej

- rolki prowadzące

Pasek pomocniczy

Pasek pomocniczy zapewnia napęd elementów układu pomocniczego: alternatorów, pomp wspomagania układu kierowniczego, pomp wody (w zależności od instalacji), sprężarek klimatyzacji...

Dlatego pasy pomocnicze SNR są:

- opracowane i zoptymalizowane pod względem długości, z tolerancjami odpowiadającymi stosowanym w oryginalnym wyposażeniu

- zatwierdzone do użytku w każdym pojeździe

Ponieważ paski pomocnicze - rowkowane lub trapezowe - mają ograniczoną żywotność, NTN zaleca:

- regularnie sprawdzać zużycie

- przestrzegać okresu wymiany zalecanego przez producenta i/lub NTN Europe

- nie odkładać wymiany uszkodzonego paska

Zestawy kół pasowych tłumika drgań wału korbowego

Jest to kompletne rozwiązanie zamienne, które obejmuje koło pasowe amortyzatora i elementy mocujące.

Koła pasowe tłumiące drgania wału korbowego redukują drgania spowodowane cyklicznymi zmianami predkości obrotowej wału korbowego. Zapewnia to najlepsze działanie paska i innych napędzanych elementów.

Wysokiej jakości koło pasowe zapewnia wysoki poziom ochrony silnika i zmniejsza ryzyko jego uszkodzenia.

160 referencji dla zestawów kół pasowych tłumika wału korbowego SNR oferują:

- płynną pracę

- wysoki poziom tłumienia i ochrony silnika

- zwiększoną żywotność

Czy wiesz, że... ? Montaż koła pasowego z tłumikiem drgań naraża śruby na ekstremalne naprężenia, czasami nawet do granicy ich elastyczności. Po zdjęciu elastycznego koła pasowego należy bezwzględnie wymienić śrubę (śruby), a jeśli na starej śrubie znajduje się podkładka oporowa, należy ją przenieść na nową śrubę!

Wolne koła pasowe alternatora

Koło pasowe alternatora redukuje wahania prędkości obrotowej wirnika alternatora związane z hamowaniem silnikiem oraz gwałtownymi zmianami prędkości oborotowej silnika. Napędza alternator podczas faz przyspieszania wału korbowego, ale nie powoduje jego wyhamowywania.

Zapewnia również ochronę i wydłuża żywotność paska i pozostałych elementów układu .

Koła pasowe alternatora oferowane przez NTN Europe są zaprojektowane tak, aby:

- sprostać warunkom pracy nowoczesnych silników, które są coraz bardziej złożone

- ograniczyć ryzyko awarii alternatora

W związku z tym zalecamy regularne sprawdzanie działania koła pasowego alternatora i jego wymianę w razie potrzeby przy każdej wymianie elementów układu napędzanego paskiem pomocniczym.

Wszystko o samochodowych częściach zamiennych w naszych broszurach Zobacz DOKUMENTACJĘ

Znajdź wszystkie części w katalogu online Otwarty sklep internetowy

Rekomendacje producenta, słowami naszego eksperta

Dzięki naszym 3 zakładom produkcyjnym (w Iwata i Nagan w Japonii oraz w Mettmann w Niemczech), NTN Europe jest głównym graczem w sektorze napędu rozrządu i osprzętu silnika. Każdego roku produkujemy ponad 10 milionów kół pasowych i ponad 40 milionów łożysk do kół pasowych, z których wszystkie są w 100% testowane i sprawdzane. Nasze doświadczenie pozwala nam również opracowywać nowe produkty i rozszerzać naszą ofertę na przyszłe rynki.