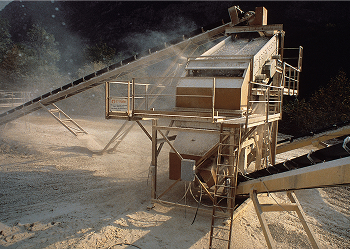

Mining and quarrying

Unlock the full potential of your operations

Reduce downtime, improve your yield

Extreme conditions, intense loads, costly downtime: mines and quarries tolerate no compromise. As a long-standing partner to the industry, NTN designs robust solutions to withstand the harshest environments. Thanks to our technologies and personalised support, we optimise equipment reliability and reduce maintenance costs.

Industry challenges

- Prevent premature wear of equipment exposed to extreme conditions

- Reducing frequent breakdowns and unplanned downtime that impact productivity

- Limit maintenance costs associated with intensive operations

- Withstand a demanding environment that pushes equipment to its mechanical and thermal limits.

- Maintain high performance levels despite intense operational constraints.

Maximise the performance and reliability of mining equipment

Solutions designed to last in extreme conditions

To meet the extreme challenges of the mining and quarrying industry, NTN Europe offers a technical solution that is up to the task: robust, high-performance and durable bearings and accessories designed to maximise productivity.

A complete range of high-performance products: tapered roller bearings, spherical roller bearings, self-aligning bearings and inserts.

- Resistance to the harshest environments: dust, shocks, heavy loads.

- Reduced maintenance, increased productivity: improved bearing characteristics, in addition to being adapted to the requirements of the sector.

- Standard or customised: solutions designed for every critical application.

- Reliability and longevity: for installations that are always operational, even in extreme conditions.

With NTN, ensure consistent performance, even in extreme conditions

Solutions designed for all mining equipment

Conveyors

Recommended products:

Recommended products:

Recommended products:

EF800: the benchmark for vibrating applications

Screens, vibrating conveyors, feeders, sorting and screening equipment, etc.

Specially designed for vibrating equipment, the EF800 bearing meets the extreme demands of these machines: heavy loads, intense vibrations, contamination and high temperatures. Its robust design incorporates reinforced sealing, an ultra-resistant cage and grease suitable for high-frequency movements. It guarantees:

- Excellent resistance to vibrations and shocks

- Extended service life even under severe conditions

- Less maintenance, increased machine availability

- Reduction in unexpected downtime on screens and conveyors

Our services to maximise the service life of your equipment

Beyond products, NTN Europe supports you in the field to improve the reliability of your installations, anticipate breakdowns and strengthen the skills of your teams.

Identification of causes of wear or failure directly on your installations, with personalised recommendations.

Advanced bearing monitoring to prevent unexpected downtime and plan interventions at the right time.

Practical, tailored sessions to train your teams in installation, maintenance and fault detection.

Assembly and lubrication kits

Ready-to-use tools and lubrication solutions to ensure optimal mounting and controlled lubrication of bearings.

Need personalised support?

Our teams are here to help you optimise your equipment and secure your production.