Skills and expertise are a breeding ground for innovation.

To build a competitive and differentiating range of solutions, the NTN Group is transforming knowledge development into a major asset.

Whether upgrading a technology or creating new growth opportunities, our experts are committed to:

- Exploring emerging technology trends

- Anticipating new uses

- Encouraging open innovation through partnerships, research programmes and theses

In addition to the challenge of maintaining a competitive advantage and increasing technical and economic performance, environmental issues are also high on the priority list.

We are harnessing our expertise to meet tomorrow's needs in terms of mobility, green business, digitisation and services.

Materials

Controlling and developing innovative materials

NTN's innovative materials have long been used for bearings, but are now being applied to transport, industrial robotics, aviation applications and machine equipment.

In a bid to meet constant changes in industrial requirements, our expertise is focused on developing bearings offering ever greater reliability, performance and value for money while reducing pollution.

Our engineering skills encompass metal materials and powders, case-hardening, plastics, elastomers and lubricants, as well as magnetic and ceramic materials. These areas require expertise in characterising and understanding the mechanical and physical properties and behaviour of the materials. Characterisation activities rely on an organisation and laboratories that are responsible for performing these physical measurements.

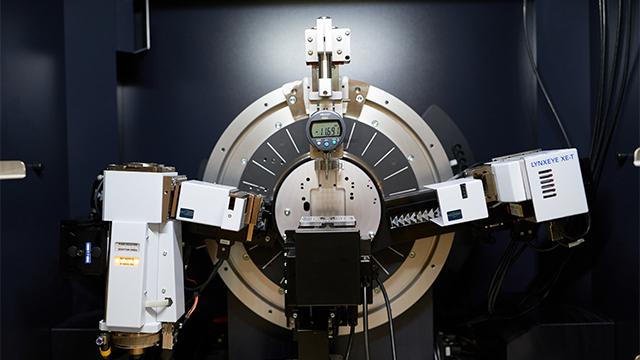

Physics and physical measurements

Analysing and characterising materials

The choice of materials determines the bearing's reliability and performance. For a clearer insight into the behaviour and properties of our materials, we use two levels of characterisation:

- Standardised tests are based on conventional measurement and analytical methods, such as mechanical extensometry tests, diffractometry and spectrometry, optical or scanning electron microscopy, magnetic particle testing, corrosion tests, and dimensional and magnetic metrology.

- Specific tests are developed to meet our needs, and our test benches allow us to test materials under real application conditions.

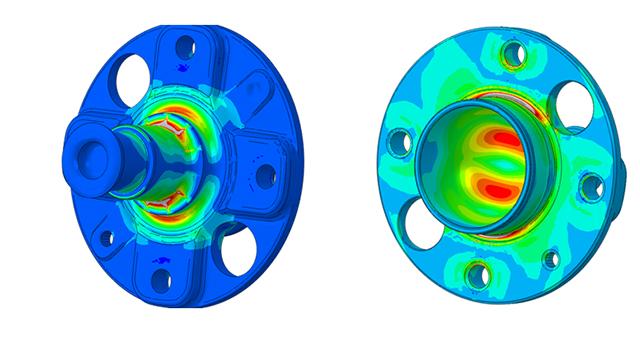

Mechanical engineering

Calculating the behaviour of complex objects

Data from the material characterisation process are used as inputs for mechanical calculations and modelling. This approach involves validating a product's mechanical strength against the external stresses and forces to which it is subjected.

The aim is to verify a system's design and sizing, improve the operation of a part or process, confirm that the right material has been chosen or comply with the requirements of a standard.

Therefore, we have specifically developed several design codes based on our recognised expertise in fundamental mechanics and tribology.

Electrotechnical engineering, electronics and microelectronics

Supporting collective challenges

The challenges involved in electric mobility, digitisation and service development are prompting our Group to expand and diversify its skills in electrotechnical engineering, electronics, microelectronics, signal processing and software development.

Process engineering

Defining and controlling the industrial process

Creating the products of tomorrow means defining and applying new processes and methods to inject superior efficiency into the production process. In relation with our prototyping, Inno Process and PTE teams, process engineering describes the material resources, conditions and operations that need to be implemented to manufacture products in line with our quality criteria.

Need more information? CONTACT US