NTN takes part in the CLEAN SKY 2 programme, Europe's largest aeronautic research programme, which brings together the industrial and public sectors.

NTN takes part in the CLEAN SKY 2 programme, Europe's largest aeronautic research programme, which brings together the industrial and public sectors.

NTN has been partnering leading aeronautics companies for more than 50 years and once again is drawing strength from its expertise to drive progress. The aim is to increase the sector's competitive edge, support innovation and reduce the environmental impact. The NTN code name is HEROe.

HEROe means High Efficiency ROller Bearing.

In this project, NTN faces the challenge of defining and designing the best hybrid roller for Airbus' Racer high-speed demonstrator.

This helicopter is intended for the emergency services, hospitals, coastguards, oil platforms, intercity transport, and so on. Therefore, it should:

The hybrid bearing that NTN is developing features tapered rollers, where the main component (metal) has been replaced with ceramic, which explains why we're calling it a hybrid.

This patented innovation has the potential to save around 15% off the bearing's total weight.

This technology also guarantees:

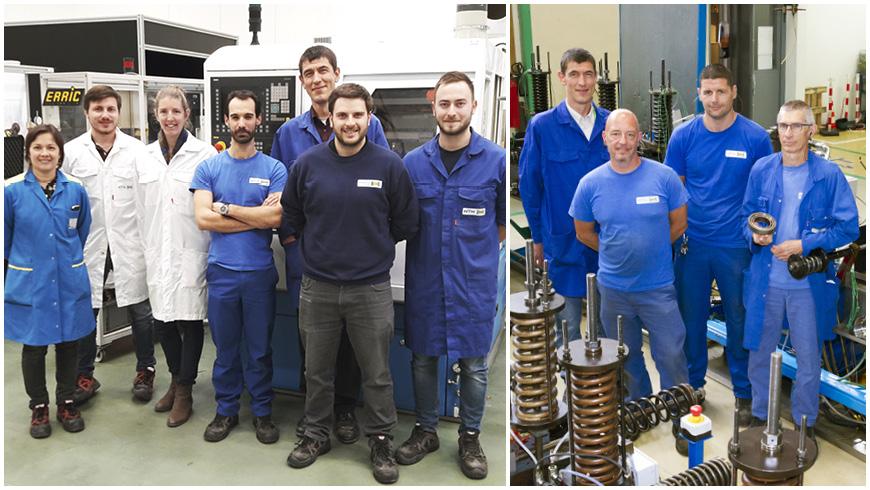

To meet these objectives, approximately, 20 NTN operators, engineers, technicians and doctors, doctors working at the Annecy and Argonay sites in France's Haute-Savoie region, have been involved in the Clean Sky 2 programme since March 2018.

The hybrid tapered roller bearing that they are designing will be mounted in the lateral gearboxes behind the propellers. This bearing "will not only help improve the aircraft's performance and reliability, but also reduce its weight and fuel consumption."

Would you like to learn more about the poject? Read the PRESS RELEASE

We started on 1 March 2018 and we are halfway through the project. To date, we have completed the entire bearing design process and we have finalised creating the prototype. Now the time has come for the test campaign, modelling and model/test correlation…

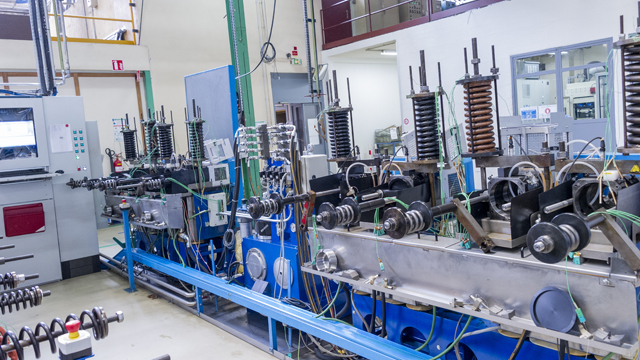

The project will require 20,000 hours of testing in our test centres in Annecy in France's Haute-Savoie region. There are different types of tests on specific machines. Test benches have been modernised accordingly and thermocouples have been added to the rotating parts to ensure measurements with greater reliability and precision.

Once the project is completed, NTN will provide GE Avio (our industry partner) with prototypes that are similar to the HEROe prototypes, but which have been engineered to suit the specific gearbox interfaces used by GE Avio. GE Avio mounts our prototypes in its subassemblies and supplies them to Airbus Helicopters.

"This project has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 785400"