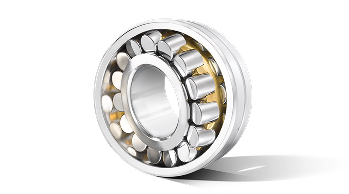

Spherical roller bearings

Designed to withstand

Unbeatable performance in severe conditions

Designed to withstand high loads and high temperatures, our spherical roller bearings (SRB) are robust and allow misalignment.

A complete range to suit all industrial applications.

Extended service life

Up to 2x longer life

in severe conditions

Optimum performance

High limiting speeds and maximum load capacities

Installation without constraints

Ready-to-use, interchangeable solutions, with no need to modify the housing.

Reduced maintenance costs

Less lubrication,

less unplanned downtime.

Spherical roller bearings designed

to last

A complete range for demanding applications

The NTN range of spherical roller bearings offers high performance, even in the most severe environments: heavy loads, misalignment, temperatures up to 200°C, pollution, etc.

Designed and manufactured in our modern factories in Italy and Japan, these bearings incorporate :

- high-quality steel

- optimised roller sizes

- optimised surface finishes

- reinforced cages in pressed steel or high-performance solid brass without a central guide ring

- specific heat treatments

- to guarantee robustness, dimensional stability and wear resistance.

Their improved design enables higher speeds, reduces operating temperatures and extends maintenance intervals. Standard, sealed or customised, they can be adapted to meet every need with reliability and efficiency.

Premium quality for enhanced performance

+24%

dynamic load

capacity

2x

longer

life

200°C

steel stability guaranteed

+20%

increase in speed

limits

Less downtime

for greater profitability

Spherical roller bearings to suit every need

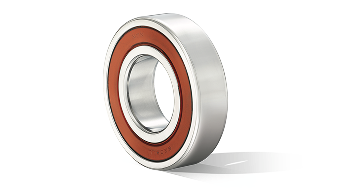

Standard (SRB)

Proven quality for lasting performance

The basic version without sealing. It offers an excellent performance/cost compromise for applications with little exposure to contamination. Easy to integrate, it's the ideal solution for clean environments or regular maintenance.

Sealed (SSRB)

Performance against pollution and infiltration

Equipped with a specially designed nitrile seal, these bearings provide a reliable seal even in the event of misalignment. Their internal design and load ratings are identical to the open versions. Pre-greased for operation at temperatures up to 70°C, they offer extended service life and greatly reduce maintenance requirements.

With metalic deflectors (Kizei)

Armoured to face the dirt.

The bearing offers exceptional durability thanks to its nitrided metal deflectors, guaranteeing resistance to impact and corrosion. Easy to fit and interchangeable with standard bearings, it reduces maintenance costs while ensuring reliable performance in demanding conditions.

Series EF800

The reinforced cage for vibratory applications

Designed for vibrating machines, the EF800 series incorporates a solid machined brass cage, with no guide ring or central shoulder, to avoid any risk of jamming. Its reduced radial clearance and specific tolerances ensure reliability, longevity and extended maintenance intervals.

Thrust

Maximum performance, even in the most extreme conditions

Designed for high axial loads, spherical roller thrust bearings are ideal for heavy environments such as presses, cranes, turbines and mining equipment. Interchangeable (ISO), they guarantee robustness with their sheet steel cage and allow a radial load of up to 50% of the axial load.

Spherical roller bearings with metal deflectors

It combines robustness, reliability and ease of integration. Its integrated metal seal provides long-lasting protection for equipment, with no need for design modifications or special housing. An ideal solution for dusty, damp or difficult-to-access environments.

- High-quality nitrided metal cage and baffles

- Interchangeable: Compatible with standard spherical roller bearings (SRB)

- Extended service life: up to 3 times longer service life

- Reduced maintenance costs: greasing frequency reduced by a factor of 3

- Extended temperature range: up to +200°C.

- Simple installation: no special tools required

- Simplified lubrication: similar process to open bearings

Designed to perform in demanding environments

Made in Italy, with expert industrial know-how

Our spherical roller bearings (SRB) are produced at ICSA S.p.A., near Turin in Italy. Specialising for over 50 years in solutions for harsh industrial environments, this site controls the entire manufacturing process: heat treatment, precision machining, assembly and laboratory quality control.

This integrated know-how, supported by modern equipment and rigorous certifications, guarantees premium parts that are durable, traceable and perfectly suited to the most critical applications.

To simplify your maintenance

ALL-IN-ONE KIT

An innovative offer at your service

Opt for KITS of spherical roller bearings (SRB): fewer references to manage, zero forgetting, easy assembly and long-lasting performance.

Do you have a project? A specific need?

Our experts will help you choose your bearings.